Why Every Orthopedic Surgeon Needs a Universal Screw Removal Set

Wiki Article

In orthopedic surgery, preparation is the foundation of success. Surgeons walk into the operating room with a clear plan, but hardware removal procedures often present unforeseen challenges. Stripped heads, cold-welded components, or outdated implant systems can turn a routine extraction into a complex ordeal. Having the right tools available makes all the difference in these high-pressure moments. This is where a universal screw removal set proves its worth as an essential asset in any surgical toolkit.

The Challenge of Hardware Extraction

Removing orthopedic implants is a common procedure, yet it is rarely straightforward. Patients may present with hardware implanted decades ago, often from manufacturers that no longer exist. Without the original extraction instrumentation, surgeons face a difficult puzzle. Trying to improvise with standard tools can lead to increased operative time, unnecessary bone loss, or damage to the surrounding soft tissue.

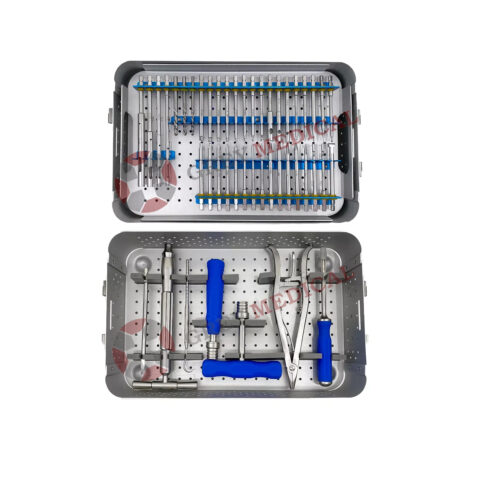

A universal screw removal set solves this problem by providing a comprehensive array of drivers, extractors, and trephines designed to engage with virtually any screw head configuration. Whether dealing with a damaged hexagonal recess or a stripped cruciate head, these specialized instruments allow surgeons to grip and remove hardware efficiently. This versatility reduces stress in the operating room and helps maintain the surgical schedule.

Key Features of High-Quality Removal Systems

The best instruments are defined by their durability and precision. When a surgeon encounters a stubborn screw, the surgical instrument must transmit significant torque without failing. High-grade stainless steel construction ensures that the extractors bite into the screw head securely rather than slipping or shearing off.

Efficiency is another critical factor. A well-organized universal screw removal set allows the surgical team to quickly identify the correct tool for the specific problem at hand. Time saved during hardware removal translates to shorter anesthesia duration for the patient and lower infection risks. The ability to adapt to different screw sizes and types—including locking, cortical, and cancellous screws—makes these sets indispensable for trauma centers and revision specialists.

Excellence in Surgical Innovation

Choosing the right manufacturer is just as important as selecting the right tool. GreyMedical® is a privately owned medical technology company dedicated to innovation and excellence in the craft of surgical instruments. Their commitment to quality ensures that surgeons have access to reliable equipment when it matters most. By focusing on the specific needs of medical professionals, GreyMedical® delivers solutions that enhance procedural outcomes.

When hospitals invest in a universal screw removal set from a reputable provider like GreyMedical®, they are investing in patient safety. These instruments undergo rigorous testing to meet the demands of modern orthopedic surgery. The confidence that comes from using superior tools allows surgeons to focus entirely on their technique and the patient's recovery.

Conclusion

Hardware removal should not be a guessing game. The unpredictability of revision surgery demands tools that are adaptable, robust, and precise. A universal screw removal set transforms potential complications into manageable tasks, ensuring that even the most stubborn implants can be removed safely. By equipping operating rooms with these versatile systems, medical facilities empower their surgeons to perform at their best, regardless of the implant type they encounter. With companies like GreyMedical® pushing the boundaries of instrument quality, the future of orthopedic extraction looks more efficient than ever.

Report this wiki page